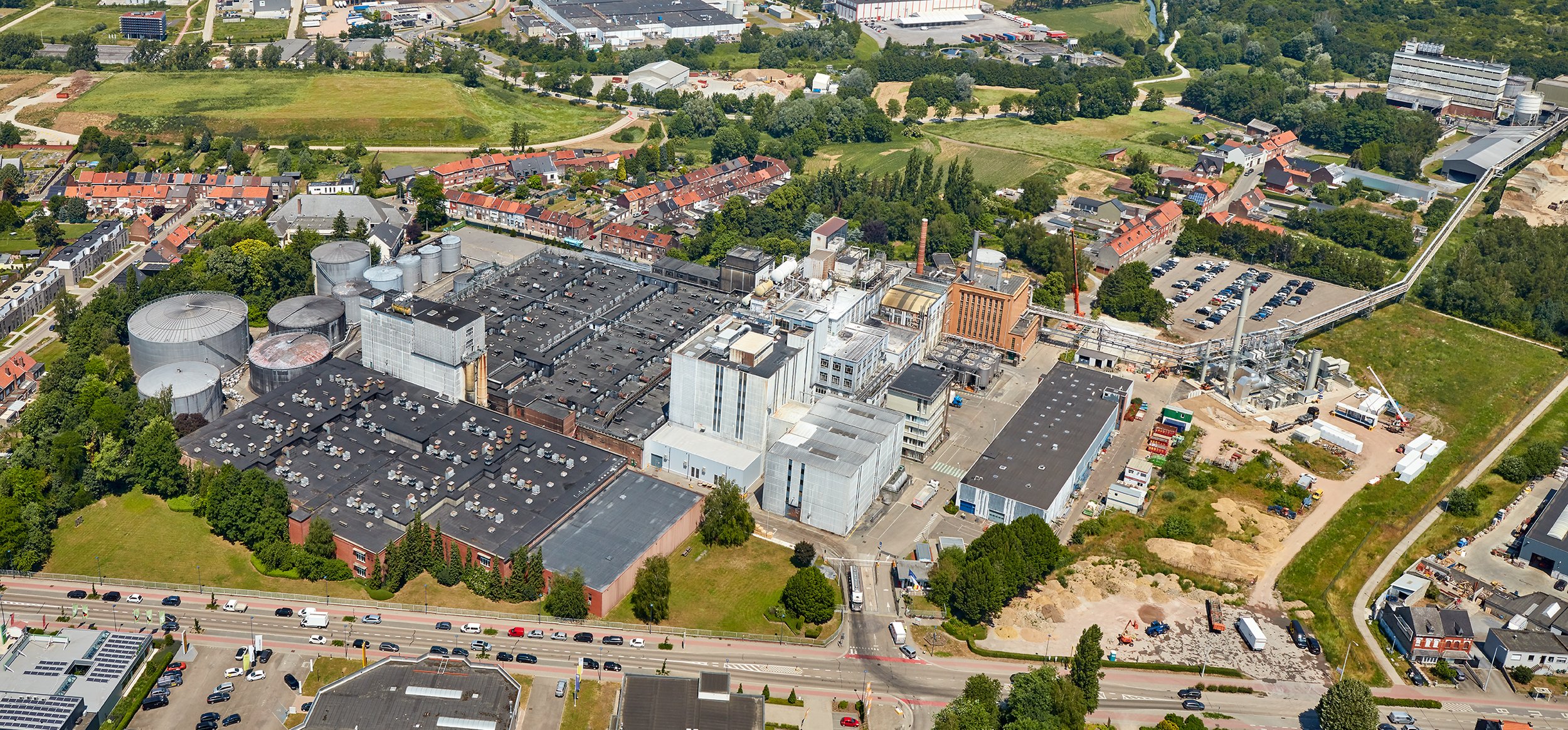

Citribel

Developing commercial applications for citric acid's co-products

#coproducts #citricacid #circularinnovation #businessdevelopment

If you’ve never heard of a company named Citribel, you’re about to discover a pioneer of circular entrepreneurship. For nearly 75 years they’ve been upcycling sugar molasses, a side stream of sugar production. Nowadays their commitment to upcycle their own side streams is as remarkable as it is unwavering. What is the state of affairs of this circular business development?

Director Sylvia Gilis explains.

Why did Citribel decide to valorize its side streams?

Sylvia Gilis, Director at Citribel:

Citribel is in fact a circular entrepreneurship pioneer. For nearly 75 years we’ve been using sugar molasses to produce citric acid. Sugar molasses are a co-product of sugar production. All the other citric acid in the world is made from corn syrup, a primary food product. Besides the fact that our core business is to upcycle a side stream, we now make every effort to upcycle our own side streams.

To understand why, I should tell you that we produce just about 100.000 ton of citric acid per year. With that, we produce more or less 200.000 ton of co-products. The previous owners never considered this an asset. When we took over the company in 2016, we did so with the explicit intention of valorizing the co-products. Through what we do with our co-products and the components contained therein, we can obtain a unique market position.

How come you generate such vast amounts of co-products?

This is due to our unique production method. We produce citric acid by means of surface fermentation. Different sugar molasses are turned into a specific mixture, which we pour into trays. We then blow spores of a fungus over this mixture under specific conditions, which kickstarts the fermentation, creating both citric acid and mycelium.

On a daily basis, we produce about 270 tons of citric acid and around 6 football fields of mycelium. Our competitors mostly work by means of submerged fermentation in deep tanks. This process is less labor intensive and requires less surface area. However, it also co-produces less mycelium and of a lesser quality.

What have you been doing with your side streams up until now?

They were and are still mainly used as animal feed and fertilizer. In particular the mycelium was difficult to preserve and transport because of the high moisture content. We’ve invested in a highly specialized drying process, meaning we can now transform it into a perfectly preservable and transportable powder. One of our other co-products, vinasse, is also mostly known for its use in animal feed. Vinasse is getting more and more attention because of its specific components. We’re constantly getting to know more about their potential application areas.

Picture: Citribel, mycelium

How did GLIMPS.bio help you?

Open mind, pragmatism, action

At Citribel, we have unparalleled knowledge about the composition and fermentation of sugar molasses for citric acid production. What GLIMPS.bio added brilliantly was the practical know-how and methodology for rapid innovation and business development. Experimenting with an open mind, swiftly involving customers and potential new customers and taking small but targeted steps forward.

Product management: linking technical and market insights

GLIMPS.bio helped us to continuously involve customers from the very first experiments, and to further develop our products according to their feedback. In this way we try to match our product as closely as possible to the needs of the customer.

Large network, lots of knowledge

GLIMPS.bio has a vast network at their fingertips, which means that they quickly find the people and information you need.

What is the result of the collaboration?

We are very satisfied with the potential of the innovation trajectories and with the clarity of focus and speed at which they are progressing.

Picture: Yann bertrand

What do you recommend to other business leaders who want to work with their side streams?

Focus and interest in your side streams form an important first step. Try to think of the steps your company would take if the co-products and by-products were your only products. Sometimes surprising conclusions are reached.

If you have the capacity to try to valorize a side stream, keep an eye out for red flags for scaling up. Even when you’re still in the lab phase. Do you need expensive or rare materials? Are there polluting production steps? Some products or applications are very interesting in their own right, but are too difficult to produce at scale.

As early as possible, check if there is a realistic market demand for your potential innovation and continue to do so repeatedly.

Picture: Yann bertrand

“When we took over the company in 2016, we did so with the explicit intention of valorizing the co-products. Through what we do with our co-products and the components contained therein, we can obtain a unique market position.”

— Sylvia Gilis, Director, Citribel

Picture: Yann Bertrand

From waste to revenue,

from fossil to bio-based.

We’ll help you from A to Z.